At A. Lange & Söhne, every watch movement is assembled at least two times to ensure the highest quality and precision.

Unique in the world of watchmaking, A. Lange & Söhne retains a steadfast protocol of double-assembling every movement it makes. “It has never been our philosophy to care about the effort,” said Tino Bobe, the company’s director of manufacturing. “We only care for the result: the highest quality and precision.” The Glashütte, Germany-based brand was originally founded by Ferdinand Adolph Lange in 1845 and was brought back to life by his great-grandson Walter Lange in 1990.

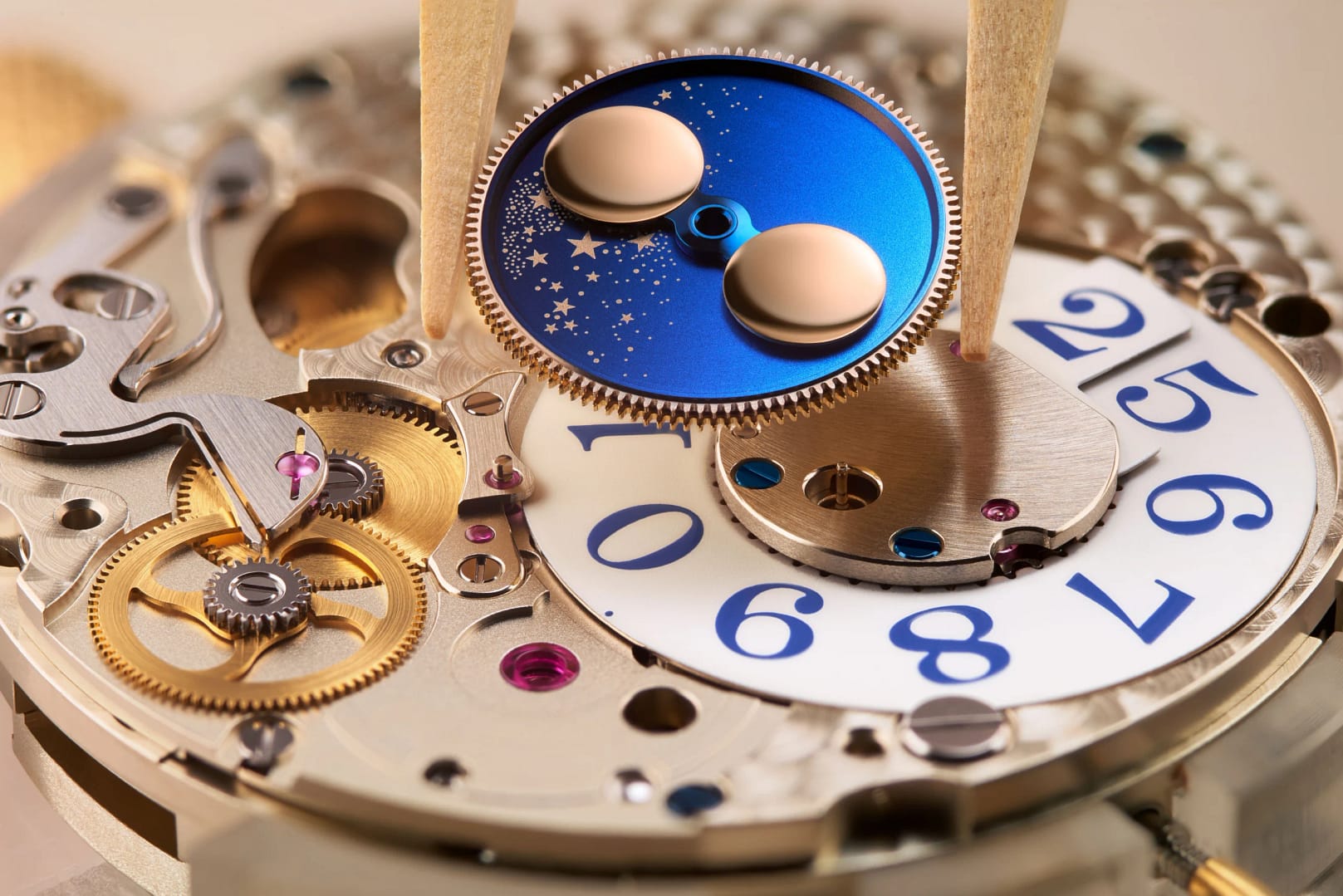

The painstaking double-assembly process involves several steps taken in a precise order. “During the initial assembly phase, the complex mechanisms of each calibre are put together with temporary assembly screws and carefully adjusted to ensure all components interact perfectly. After the first assembly, the movement is checked and regulated—then it is taken apart down to the last wheel,” Bobe explained. Usually, just a single watchmaker works on the entire movement from start to finish.

A Stabilizing Silver Plate

Every Lange watch movement is anchored with a German silver plate, a metal alloy made of copper, silver and zinc. Ferdinand Adolph Lange used this silver in his pocket watches starting in the 1850s, soon after he started his business. The German silver “is responsible for the rigidity of the movement,” said Bobe, and it “stabilizes the entire wheel train beneath a single bridge.” Untreated German silver “is our material of choice for plates, bridges and balance cocks.” Over time, the metal will develop a “warm, golden patina that protects its surface and brings out the elaborate finishes particularly well. That is why the material is left ‘untreated.’”

Gearing Up

The alloy requires careful handling, however, during both the initial and second assemblies, Bobe said. The unique characteristics of German silver “are definitely among the greatest challenges our watchmakers have to face. During the first assembly of the movement, even an experienced watchmaker has to mount and dismount the three-quarter plate several times, until every toothed wheel of the wheel train has the ideal endshake. Since every fingerprint can leave a lasting blemish, our watchmakers wear finger cots when handling the material. It is also very sensitive to scratches and needs to be re-finished before final assembly.”

Once the movement is taken apart again after the initial assembly, each component is checked for scratches and thoroughly cleaned. Even a tiny scratch will require an additional polishing. “Each part is cleaned, the assembly screws are replaced with flawless blued steel screws and the gold chatons are polished. Delicate finishing techniques, such as the Glashütte ribbing or black polishing, are applied just before the final assembly—even to parts that will not be visible through the sapphire-crystal caseback.”

Lubricating the Movement

But that’s not all. Every watch movement requires minute amounts of oil in specific locations in order to avoid friction between its moving components. A Lange watch “is carefully lubricated at over 50 oil sinks and bearing points with up to eight different greases and oils,” Bobe explained.

A Singular Achievement

For a casual observer, being the single watchmaker who builds a Lange movement sounds like a lot of pressure, but it is also a valuable learning process, serving to hone and perfect a watchmaker’s skills.

“Instead of several watchmakers being involved in the assembly, we usually have a single watchmaker work on a movement from start to finish, meaning both first and final assembly,” Bobe said. “This has the advantage that we can ensure the greatest possible precision on the one hand, while continuously expanding the expertise of our watchmakers on the other.”

Undoubtedly, Ferdinand Adolph Lange would be proud of the exacting craftsmanship behind every watch that bears his name. His motto—“there is something one should expect not only of a watch but also of oneself: to never stand still”—resonates with the brand to this day.